Common Fault Phenomena And Handling Methods Of Laser Marking Machine

Common Fault Phenomena And Handling Methods Of Laser Marking Machine

The laser marking printer does not have ink system faults, so the failure rate of the laser marking printer is relatively low. It shows stability and reliability in the inkjet process of the production line, and the printing effect is clear, which has been unanimously recognized by customers. But this does not mean that lase marking printers do not malfunction or have technical problems, especially since laser marking printers do not have consumables, which makes the service provided by laser marking printer manufacturers higher in door-to-door service costs compared to ink inkjet printers. Therefore, it is particularly important for laser marking printer users to understand the common causes and solutions of laser marking printer faults. Today, the editor of Chengdu Linservice Industrial Printing Technology Co., Ltd. will introduce the common faults and solutions of laser marking printers during use.

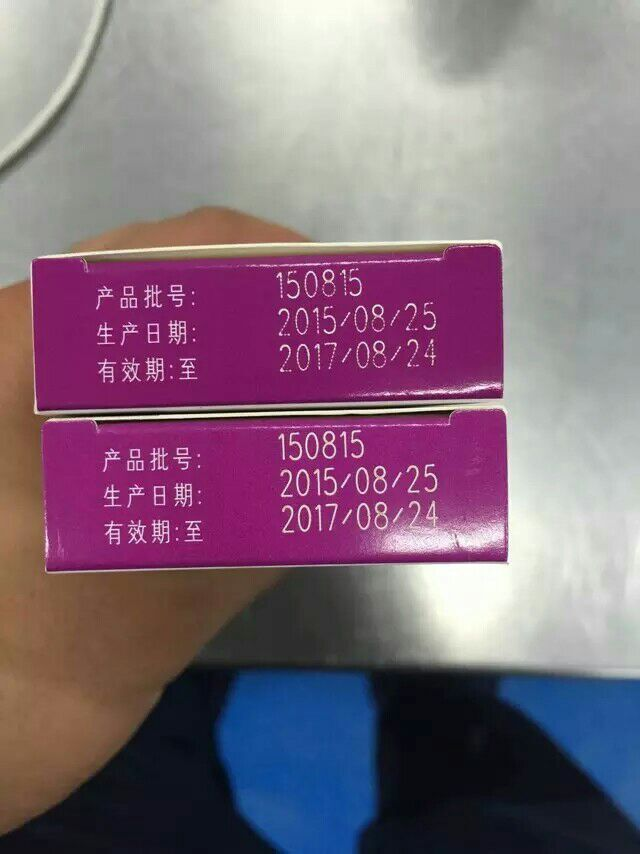

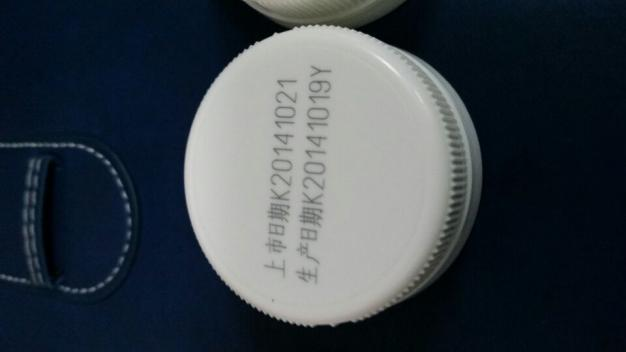

After nearly 10 years of rapid growth, a large number of factories have started using laser marking printers for product identification. By using laser marking printers to achieve higher clarity, better anti-counterfeiting effect, and can improve the level of product identification, the identification effect can be achieved. With the increase of ownership, laser marking printers, as a type of inkjet equipment, inevitably encounter various problems and malfunctions. How to quickly handle and reduce the production impact caused by equipment shutdown has become the most concerned issue for operators and users. The common faults of laser marking printers are as follows:

1. The deformation of the laser marking printer's font or the difference in the depth of the printed font result in unclear printing effect. This situation is mostly caused by the energy attenuation of the laser generator or the fast online speed; with the increase of usage time, the laser tube of the laser marking printer will decay with the increase of light emission, which will also encounter the problem we mentioned above. The printing effect is not clear, and the feeling is very faint. How to handle it? If it is a CO2 laser machine, based on the usage time, the manufacturer generally recommends a laser tube inflation plan of 2 or 3 years. If the usage time is short and the marking is unclear within 1 year, the power can be increased or the marking speed can be reduced. Increasing the power of the laser tube is a common treatment method. As for the difference in font printing depth, it is also a common malfunction of laser marking printers, and it may also be caused by poor laser focusing. As we mentioned above, the working principle of a laser machine is to emit laser light through a laser tube, deflect it through a polarizing mirror system, burn it on the surface of the product, undergo physical and chemical reactions, and form characters, which can be deep or shallow. One thing we need to pay attention to here is the focus point, which is the adjustment of the focal length. Some laser machines on the market have the function of red light positioning and focusing, which can be clicked and two red lights appear. When the red light gathers together, the focal length is the best time, at which point a clearer spray printing effect can be achieved on the surface of the product.

2. After the laser marking printer is turned on, there is no response. Firstly, check the power system to see if there is a power input at the flat panel display port. If the power supply to the power system is abnormal, there will be no response when the machine is turned on; if there is a power input, consider whether the operating system is caused by computer lag. Laser marking printers generally use customized operating systems, standard boards, and computer systems. Common software systems on the market are generally developed based on the WINDOWS platform, and have high performance requirements for computers. If the computer configuration is low, it is easy to get stuck. If you encounter the inability to access the operation interface after turning on the computer, it is recommended to first perform antivirus upgrade processing on the computer. If it still does not work, you can contact the laser machine supplier for remote software reset or upgrade processing.

3. The other common faults and problems of laser marking printers mentioned here cover a wider range, including some relatively rare fault problems, such as laser machine not emitting light, garbled code, system failure, low memory, no response when starting up, power box failure, static code cannot be set, variable QR code cannot be printed, communication cannot be connected, and so on. Classifying other faults and problems mainly takes into account these issues. Without systematic training, it is difficult for general operators to determine the cause of faults and handle them, and they must seek technical support from manufacturers.

Chengdu Linservice Industrial Inkjet Printing Technology Co., Ltd. has been focusing on the inkjet marking industry for more than 20 years, focusing on the application and development of laser technology in the industrial field, providing customers with overall laser marking system solutions. The company focuses on the research and application of laser marking technology, specializing in providing CO2 laser marking machines, fiber laser marking machines, UV laser marking machines, etc. It is a professional manufacturer of laser marking machines and a well-known provider of laser inkjet machine applications. The company effectively integrates laser technology and computer technology, listens attentively to customer needs, assists customers in analyzing production application processes, and designs efficient and safe identification solutions for customers, thereby helping customers solve the problem of laser identification. For more information, please follow our website or call: +8613540126587.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba Javanese

Javanese Divih

Divih Philippine

Philippine Gwadani

Gwadani Kurde

Kurde

Application of TTO Printer

Thermal transfer printer (TTO Printer) plays an important role in modern industry and is widely used in many fields, especially in the food, medicine, daily necessities and electronic product packaging industries. Its main function is to print the production date, shelf life, barcode and other information on various packaging materials through thermal transfer technology.

Read More24mm TTO Printer VS 32mm TTO Printer

24mm TTO printers and 32mm TTO printers have their own characteristics in technical specifications and are suitable for different needs. 24mm TTO printers usually attract SMEs with their compact design and lower cost, suitable for printing smaller barcodes and labels, and the speed can usually reach 300mm per minute. In contrast, 32mm TTO printers offer a wider printing format, suitable for larger packages, and can also reach a speed of 400mm per minute, suitable for efficient production lines. Both support a variety of ink types and have excellent print clarity and durability, which can meet the needs of different industries.

Read MoreHow Does a UV Laser Marking Machine Work?

The working principle of a UV laser marking machine revolves around the process of photochemical ablation. When the UV laser beam hits the surface of a material, it breaks the molecular bonds directly without generating significant heat, unlike traditional laser marking methods. This “cold” marking process ensures that the surrounding material is not damaged or altered, which is particularly beneficial for marking sensitive materials like plastics, glass, and certain metals.

Read More