The Maintenance And Upkeep Details Of The Inkjet Printer Determine The Maintenance Rate.

The Maintenance And Upkeep Details Of The Inkjet Printer Determine The Maintenance Rate.

The repair and maintenance of the inkjet printer are two aspects during the use of the inkjet printer. The repair of the inkjet printer refers to the troubleshooting and restoration of the inkjet printer after a malfunction occurs; the maintenance and upkeep of the inkjet printer belong to the details during its use, which determine the failure rate of the inkjet printer. This is the experience accumulated by Chengdu Linservice in more than 20 years of communication with clients. The inkjet printer belongs to technological electronic products, and it is inevitable to encounter some problems in daily use. For some minor issues, the operator of the inkjet printer can refer to the user manual for handling. The handling process must follow the requirements and steps of the manual to avoid other problems. We also provide electronic user manuals and training videos for the inkjet printer for the HK8300 small character inkjet printer and LS716 large character inkjet printer from Chengdu Linservice. If there are some problems that are not listed in the manual, it is recommended that you do not blindly disassemble the internal parts of the inkjet printer. Often, some people who do not understand will disassemble them randomly, which can lead to larger problems. So if there are technical problems with strong professionalism, it is best to contact professional inkjet printer manufacturers such as Chengdu Linservice or supporting after-sales service personnel. If necessary, you can also directly return to the factory for repair.

Many people have heard the phrase "details determine success or failure". In the use and maintenance of inkjet printers, we also encounter various problems, and sometimes small details are the key to solving the problem. If we do not pay attention, the problem is often solved at the time, and the same fault will occur again later. Chengdu Linservice's years of experience in inkjet printers have taught us that there are various problems with inkjet printers, some of which are within our understanding and have been addressed. Sometimes, we can quickly identify the root cause and details, and provide targeted solutions. Some faults are very unreasonable, appearing inexplicably, even repeatedly, or intermittently. After normal use for a period of time, faults occur, and sometimes this situation occurs. The technical personnel have no problems at the code spraying site, but the fault occurs shortly after leaving, which greatly prolongs our maintenance work time and is difficult to solve in a short time. Today, the editor of Chengdu Linservice will discuss with you the three major details of inkjet printer maintenance to make maintenance more convenient:

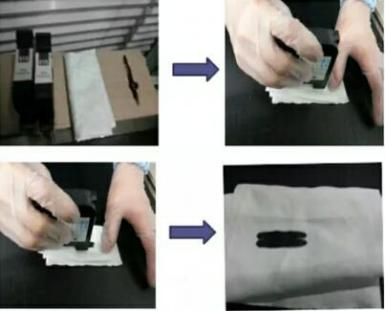

1. Problem with the nozzle part of the inkjet printer: The nozzle of the small character inkjet printer is mainly composed of an ink discharge tube, a recycling tube, a cleaning tube, a circuit line, a nozzle, a spray chamber, a high-pressure deflection plate, a recycling tank, a phase detector, a charging tank, and other parts, which are the most prone to problems in the inkjet printer. Our inkjet printer ink is easy to dry and solidify, with a time of about 0.3 seconds. If not used for a long time or stopped abnormally, it can easily cause ink accumulation inside the pipeline and nozzle, leading to pipeline blockage. In case of such a problem, we must carefully judge which pipe has the problem, and then gradually get through. The nozzle is seriously blocked, so we can use Ultrasonic cleaning to achieve efficient and rapid treatment.

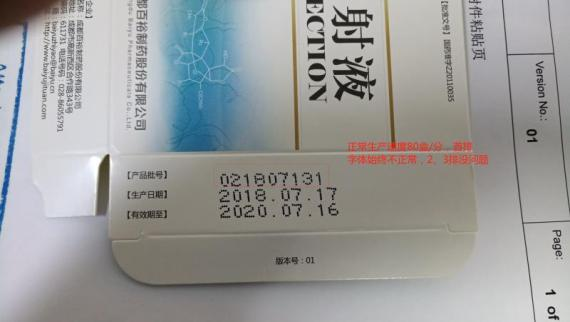

2. Unclear, blurred, or scattered font during inkjet printing: In addition to the cleaning of the nozzle and filter before cleaning the nozzle mentioned earlier, we should also learn to conduct preliminary diagnosis and testing from the circuit part to avoid unclear, scattered, or unstable ink lines caused by circuit charging or calibration issues. The details of the circuit include measurement of charging calibration, pressure calibration, high-voltage measurement, ground wire detection, and other aspects. At this time, we need a universal meter for auxiliary work. The use and operation of the universal meter are also essential to learn. To become a master of inkjet printer maintenance, it is necessary to understand some circuit knowledge and start from the circuit ink path separately, which is a faster and more stable way for us to solve problems.

3. The inkjet printer needs regular maintenance: After using it for a certain period of time, the inkjet printer prompts that the service time is up. At this point, your inkjet printer needs maintenance. This is the same principle as when your car reaches a certain mileage and needs maintenance, but most inkjet printer users overlook this point. I don't think it matters much without maintenance, and the machine can still be used normally. There is no need to spend this cost or wait until the machine cannot be used together for maintenance and repair. Little did they know that such neglect not only incurs higher maintenance costs in the later stages of the inkjet printer, but also reduces its service life, leading to the equipment losing value earlier. On the basis of knowing the working principle of the inkjet printer, we are well aware that regular maintenance and upkeep of the inkjet printer can not only avoid unnecessary malfunctions, but also ensure that our inkjet printing effect always maintains the best quality. Only in good working condition can we achieve twice the result with half the effort.

4. Frequent turning on and off of the inkjet printer results in too thin ink, which affects the printing effect. This situation is also common among the customers encountered by Chengdu Linservice. Many customers, especially some small production enterprises, have low production capacity and may only use a few hours a day. Even when people leave, they have to turn off the printer frequently, which can easily cause too thin ink depth, unclear printing, and even affect the normal use of the machine. In the end, only the ink can be replaced. Some customers feel that running the machine when not in use would waste consumables, but every time the inkjet machine is turned off, it automatically cleans the nozzle. The solvent in the solvent box is cleaned and then recycled back into the ink box. Frequent switching on and off of the machine will make the ink thinner and thinner, and the loss of consumables caused by replacing the ink is much higher than the cost of consumables volatilization caused by running the machine when not in use. Therefore, when providing training to customers, engineers must remind them not to frequently switch on or off the machine.

After discussing the details of the maintenance and repair of the inkjet printer mentioned above, it is believed that users have gained a brand new understanding and understanding of our labeling equipment. Repairing inkjet printers requires meticulous work, a good mindset, and unremitting efforts. With careful and responsible learning and operation, the inkjet printer will ultimately become your right-hand arm and a helping hand in production. In addition, with the progress of technology and the development of the times, Chengdu Linservice Industrial Inkjet Printing Technology Co., Ltd. will keep up with the times and search for better quality, faster speed, lower price inkjet marking equipment to provide to everyone. If you encounter any problems with the inkjet printer during use, please feel free to call for consultation.

Chengdu Linservice Industrial Ink jet Printing Technology Co., Ltd. is an old brand enterprise in the code jet marking industry. It has focused on the code jet marking industry for more than 20 years. In 2011, it was awarded the top ten famous brands of China's code jet printing machine by the China Foods Limited Packaging Machinery Association. The company has a rich identification product line, providing a full range of products including color band coding machines, TTO intelligent coding machines, laser coding machines, small character inkjet coding machines, large character inkjet coding machines, handheld inkjet coding machines, barcode QR code inkjet coding machines, laser coding machines, invisible ink inkjet coding machines, and inkjet coding machine consumables. It is a well-known supplier of inkjet coding machine identification products and traceability systems in the industry. Adhering to the service concept of "Professionalism creates higher value for customers", the company provides customers with a full range of identification solutions and a full range of pre-sales and after-sales services, including: professional technical consultation, pre-sales sample printing, inkjet printer trial, professional installation and training, quick technical support, and sufficient supplies of consumables and spare parts. For more information, please visit our company website at www.linsch.cn. For more information, please call: +8613540126587.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba Javanese

Javanese Divih

Divih Philippine

Philippine Gwadani

Gwadani Kurde

Kurde

What is Online Inkjet Printer?

With the rapid development of modern printing technology, Online Inkjet Printer, as an efficient and accurate printing device, is being adopted by more and more enterprises and industries. It is not only suitable for ordinary printing tasks, but also plays an important role in many occasions that require high-quality and fast output. So, what is an online inkjet printer? What are its unique advantages and applications?

Read MoreUV Handheld Inkjet Printer: The Future of Portable Printing Solutions

In today’s fast-paced industrial and commercial environments, the demand for efficient, high-quality, and portable printing solutions is at an all-time high. The UV Handheld Inkjet Printer is quickly gaining popularity as a versatile tool for a wide range of applications, offering businesses a mobile, on-the-spot printing solution with unparalleled flexibility and precision.

Read MoreWhat is the characteristic of inkjet printer

Inkjet printers have become a popular choice in both home and office settings due to their unique characteristics.

Read More